GRC: The Eco-Friendly Innovation Material That Transformed Construction

GRC Construction Material Explained

Have you ever wondered what material is behind those stunning modern architectural marvels? Well, wonder no more because we're about to dive into the world of GRC construction material. GRC, or Glassfiber Reinforced Concrete, or even more GFRC in the American continent, is a versatile and innovative material that has revolutionized and reinvented the architecture industry.

In the world of construction, innovation and sustainability have become paramount concerns. As the industry seeks to minimize its ecological footprint and enhance the durability of structures, a remarkable material has risen to prominence – glass fiber-reinforced concrete, commonly known as GRC.

This revolutionary construction material has been transforming how we build, offering a blend of versatility, strength, and eco-friendliness that sets it apart from traditional options. In this article, we delve into the wonders of GRC, its benefits, applications, and how it's shaping the future of construction.

|

| There are many ways to use GRC, mainly in elevations, especially in organic or parametric styles. Photo: artisticrenditions. pro |

What is GRC?

As mentioned earlier, GRC, short for Glassfiber Reinforced Concrete, is a composite material that combines the qualities of concrete and glass fibers. It's composed of cement, fine aggregates, water, polymers, and alkali-resistant glass fibers. This combination results in a material that is not only structurally robust but also lightweight and flexible.

What are the Different Types of GRC?

Each type of GRC offers unique advantages and is chosen based on factors such as project requirements, design complexity, transportation considerations, and on-site conditions. The versatility of GRC allows architects and builders to choose the most suitable type for their specific project needs, whether it's achieving intricate detailing, creating innovative shapes, or meeting sustainability goals.

It comes in various types, each tailored to specific customized applications and requirements. The most commonly used types of GRC include:

- Sprayed GRC: Also known as "spray-up" GRC, this type involves spraying a mixture of cement, sand, water, polymers, and glass fibers onto a mold or formwork. This method allows for the quick and efficient application of GRC to create complex shapes and forms. Sprayed GRC is often used for large-scale projects such as building facades and cladding.

- Premix GRC: Premix GRC involves the manufacture of precast panels or elements using a factory-controlled process. In this method, the GRC mixture is prepared at the production site and then poured into molds to create various components. Premix GRC is popular for its consistency in quality, ease of production, and suitability for both intricate designs and larger panels.

- GRC Fabric: GRC fabric is a flexible form of GRC that resembles a textile sheet. It consists of cement, sand, polymers, and glass fibers that are impregnated into a fabric matrix. GRC fabric can be draped, folded, and molded into various shapes, making it an excellent choice for creating curved and free-form designs. It's commonly used for sculptures, art installations, and complex architectural details.

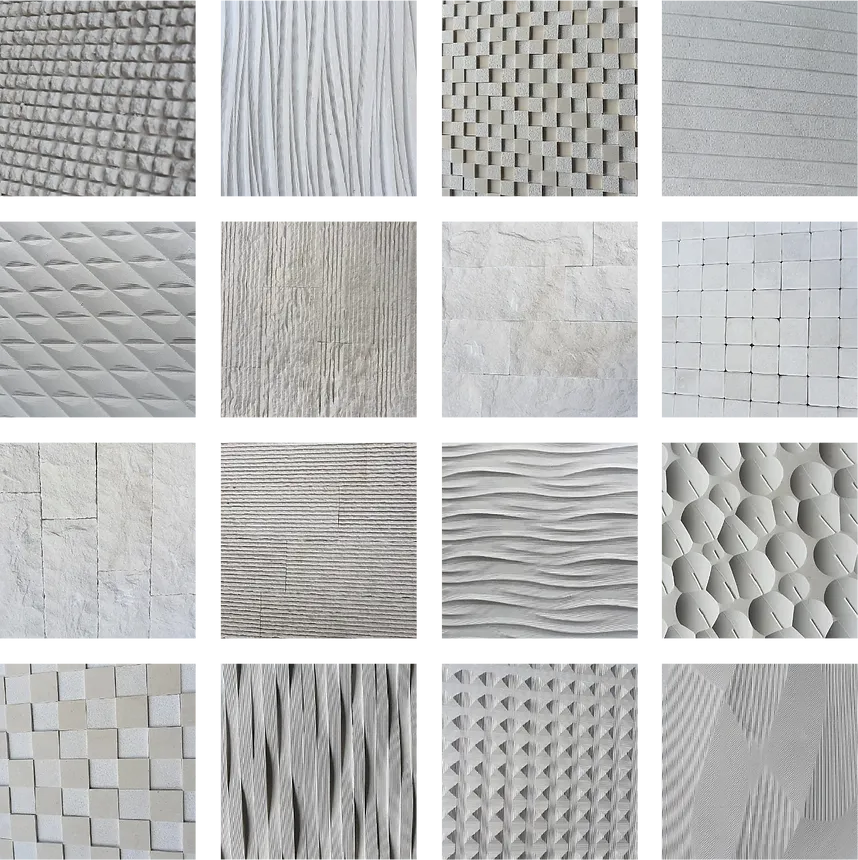

|

| Multiple textures and patterns used in GRC material, Photo: i.pinimg.com |

- Spray Mix GRC: Spray mix GRC is a variation of the spray-up method, where the GRC mixture is sprayed onto a mold to create thin and lightweight panels. This type of GRC is often used for cladding, partitions, and other applications where weight reduction is important.

- Premix/Hand Spray GRC: This type combines the features of premix GRC and spray-up GRC. The bulk of the GRC is precast in a factory environment, while specific areas that require thicker layers or manual detailing are hand-sprayed on-site. This approach allows for a balance between efficiency and customization.

- GRC Elements: GRC elements are precast components that are manufactured in controlled conditions and then assembled on-site. These elements can include columns, beams, balustrades, and more. GRC elements are favored for their ease of installation and ability to replicate traditional architectural features.

Benefits and Characteristics of GRC

- Strength and Durability: Despite its lightweight nature, GRC exhibits exceptional strength and durability. The incorporation of glass fibers significantly enhances its tensile strength, making it capable of withstanding various stresses without compromising its structural integrity.

- Versatility in Design: GRC material offers architects and designers unprecedented freedom in shaping their visions. Its pliable nature enables intricate detailing and the creation of complex shapes that might be challenging with traditional materials.

- Weight Reduction: Traditional concrete is known for its heaviness, which can lead to challenges in transportation and construction. GRC's lightweight properties make it easier to handle, reducing transportation costs and construction time.

- Weather Resistance: GRC displays remarkable resistance to harsh weather conditions, including freeze-thaw cycles, rain, and sunlight. This attribute contributes to the material's longevity and reduces maintenance requirements.

- Eco-Friendliness: Sustainability is a driving force in modern construction. GRC's composition often includes recycled materials, and its lightweight nature leads to decreased energy consumption during transportation. Moreover, its durability means fewer replacements, reducing waste in the long run.

Applications of GRC: Fields where GRC Can be Used

Glassfiber Reinforced Concrete (GRC) is a versatile construction material that finds a wide range of applications in both architectural and structural contexts. Its unique combination of strength, lightweight properties, and design flexibility makes it suitable for various purposes. Here are some common uses of GRC:

- Architectural Facades: GRC is widely used for creating stunning and intricate facades on buildings. Its ability to mimic traditional architectural styles while offering modern advantages makes it a popular choice for adding aesthetic appeal to structures.

- Cladding: GRC panels serve as excellent cladding materials, protecting buildings from weather elements while enhancing their appearance. GRC cladding can be applied to both new constructions and renovations, offering a fresh look to existing buildings.

- Decorative Elements: GRC is favored for crafting decorative features such as moldings, cornices, rosettes, and other ornamental details. Its lightweight nature allows for the creation of elaborate designs that might be challenging to achieve with traditional materials.

- Sculptures and Art Installations: GRC's versatility makes it an ideal medium for sculptors and artists to create large-scale sculptures and installations. Its durability ensures that these artworks can withstand outdoor conditions while maintaining their visual appeal.

- Interior Design: GRC can be incorporated into interior spaces to add a touch of elegance and uniqueness. It's used for creating features like fireplaces, columns, wall panels, and custom furniture pieces.

- Landscape Architecture: In outdoor settings, GRC is utilized to craft elements such as planters, fountains, pergolas, and benches. Its resistance to weather conditions ensures that these structures remain aesthetically pleasing and functional.

- Building Restoration: GRC is a popular choice for restoring historical and heritage buildings. It allows for replicating intricate details and patterns while maintaining the structural integrity of the original design.

- Urban Furniture: GRC is used in the creation of street furniture such as benches, litter bins, and bike racks. Its lightweight nature makes installation and maintenance easier.

- Commercial Spaces: GRC can be found in shopping malls, hotels, and commercial complexes, where its aesthetic appeal and durability contribute to the overall ambiance and longevity of the space.

- High-Rise Construction: GRC's lightweight properties make it suitable for high-rise buildings, as it reduces the load on the structure without compromising strength.

- Public Art: GRC is a favorite material for public art installations due to its ability to create unique shapes and withstand outdoor conditions.

- Infrastructure Projects: GRC can be used in infrastructure projects like bridges, tunnels, and transportation hubs to create durable and visually appealing structures.

- Exhibition Spaces: GRC can be used to create temporary exhibition structures due to its quick assembly and lightweight properties.

The versatility of GRC allows architects, designers, and builders to bring their creative visions to life while meeting structural and functional requirements. Its ability to offer strength, durability, and design freedom positions GRC as a key player in modern construction and architectural innovation.

GRC's Role in Shaping the Future of Construction

As the construction industry strives for a greener and more sustainable future, GRC material is emerging as a frontrunner in this endeavor. Its ability to combine strength with lightweight properties not only reduces the environmental impact of construction but also improves energy efficiency during transportation and installation.

Moreover, its versatility fuels a new era of architectural design, enabling the construction of structures that were previously deemed impractical or too costly.

Remarkable Worldwide Projects that Used GRC in Their Construction

The world of construction is witnessing a transformation, with architects and builders increasingly turning to innovative materials to bring their ambitious visions to life. Glassfiber Reinforced Concrete (GRC) has emerged as a game-changer, offering a unique blend of strength, versatility, and sustainability. Let's take a journey around the globe to explore some remarkable projects that have harnessed the potential of GRC in their construction.

1. The Louvre Abu Dhabi, UAE

This iconic museum, located on Saadiyat Island, is a testament to the beauty and versatility of GRC. Designed by renowned architect Jean Nouvel, the Louvre Abu Dhabi boasts an intricate, latticed dome that spans nearly 180 meters in diameter. This awe-inspiring structure is made possible by GRC panels, which provide the appearance of woven fabric while allowing diffused sunlight to create a mesmerizing play of light and shadow within the museum.

2. Petronas Towers, Malaysia

The Petronas Towers, once the tallest buildings in the world, are an architectural marvel in Kuala Lumpur's skyline. These towers incorporate GRC in their façade panels, which not only enhances their aesthetics but also contributes to their structural integrity. GRC's lightweight nature was particularly advantageous in constructing these towering skyscrapers. Read more »

3. Marina Bay Sands, Singapore

The iconic Marina Bay Sands complex in Singapore is famous for its distinctive design, which features a rooftop park supported by three soaring towers. GRC played a pivotal role in creating the stunning rooftop structure, providing a lightweight yet durable solution for the complex's unique architectural demands.

4. One World Trade Center, USA

The resilience and strength of GRC were put to the test in the construction of the One World Trade Center in New York City. This towering symbol of resilience and remembrance features GRC panels that line the tower's base, adding a touch of elegance while ensuring the building's durability in the face of challenging weather conditions. Read more »

5. Grand Lisboa Palace, Macau

The Grand Lisboa Palace in Macau showcases the creative potential of GRC in crafting intricate and ornate designs. The façade of this grand resort complex is adorned with delicate GRC elements that draw inspiration from traditional Chinese motifs, creating a harmonious blend of modern architecture and cultural heritage.

6. Sheikh Zayed Grand Mosque, UAE

Another architectural marvel in the United Arab Emirates, the Sheikh Zayed Grand Mosque in Abu Dhabi, boasts a breathtaking combination of Islamic and contemporary design. GRC was used to craft the mosque's intricate domes, arches, and minarets, allowing for delicate detailing and maintaining the structure's longevity. Read more »

|

| Sheikh Zayed Grand Mosque in Abu Dhabi, Photo: Photo by Sarath Raj |

These remarkable projects spanning the globe demonstrate that Glassfiber Reinforced Concrete (GRC) is not just a construction material; it's an enabler of architectural innovation. From the grandeur of museum domes to the intricate detailing of modern skyscrapers, GRC's strength, lightweight nature, and design versatility have left an indelible mark on the world's most iconic structures.

As the construction industry continues to prioritize sustainability and creativity, GRC stands as a testament to the limitless possibilities it offers to architects, builders, and dreamers worldwide.

Final Thoughts

Glassfiber Reinforced Concrete (GRC) material is undoubtedly a game-changer in the construction industry. With its impressive blend of strength, durability, and design versatility, it's rewriting the rulebook of construction materials.

As architects, designers, and builders continue to embrace sustainable and innovative solutions, GRC's star is destined to shine even brighter, sculpting a more resilient and visually captivating urban landscape for generations to come. Embrace the future of construction today with GRC – a material that's not just built to last, but built to inspire.

.png)